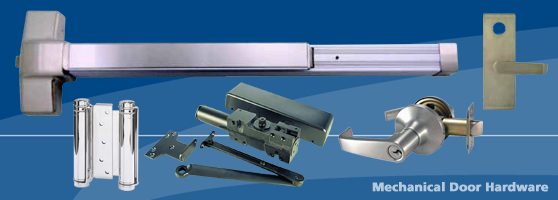

What to consider when choosing mechanical door hardware

Selecting the right mechanical locking solution for your application requires you to consider how your opening needs to function. There are many choices and options available.

Is the door that needs to lock considered high traffic? If so a heavy duty, Grade 1 lock should be chosen.

Does the door need to latch each time it closes, as on a fire rated door? A product with a spring latch could be suitable while a deadbolt alone would not.

Using high quality door hardware is very important. What separates high quality locks from those that are inferior is often the appearance of the overall design and finish. High quality locks also have a good feel to them when handled and operated. Poor quality locks often have a loose, sloppy feel when used.

The right product is only right if it’s available for you to use. Be sure to ask what the lead time is for a product you are thinking of using on your next project.

Fortunately there are many high quality lock options available at reasonable prices with short lead times.

The three most popular mechanical lock options

The three commonly used commercial lock types are Cylindrical, Mortise and Exit/Panic.

Cylindrical locks require two cylindrical holes to be drilled in the door. One hole (typically 1” diameter) is drilled through the edge of the door for the latch. The second hole is drilled from the outside face of the door to the inside face of the door (typically 2-1/8”). This style of lock is popular because of price and because the door preparation is simple.

Mortise locks use a rectangular case and therefore a rectangular cavity is needed in the edge of the door. For hollow metal doors the preparation is straight forward but it is more challenging for wood doors and can add to the overall cost of installation. Mortise locks are the heaviest duty and feature rich version of lock, and can last the life of a building if installed correctly and properly maintained.

Mortise and Cylindrical locks are available with many function options. The most commonly used functions include passage, privacy, storeroom and entrance.

A passage function lock has handles that can always be turned to retract the latch, they never lock. A privacy function lock has a button or thumb-turn on the inside of the door, which can lock the outside handle. In case of emergency, privacy function locks can be opened from the outside by using a simple tool such as a coin or poking implement.

Storeroom locks have an outside handle that is always locked and never turns and an inside handle that never locks and can always be turned. To open a door with a storeroom function lock, from the outside, a key is required which will retract the latch allowing the door to be opened.

Entrance function locks allow the user to choose if the outside handle is locked by using a key. The outside handle can be left in either the locked or unlocked state. From the inside the handle can always be turned to allow free exit.

Exit devices (or panic devices) are used primarily on doors that have been designated as being in a path of exit (path of egress). They have long horizontal bars which allow a simple pushing action on the device to unlatch the door, allowing it to swing outwards. This type of lock is available in four common variations rim, mortise, surface vertical rode and concealed vertical rod.

Rim exit devices are surface applied and may only require screw holes to mount. Mortise exit devices incorporate a locking component that is installed inside the locking edge of the door. Surface vertical rod exit devices lock the door at the top and bottom and have interconnecting rods that are attached to the inside face of the door. Concealed vertical rod exit devices also latch the door at the top and bottom but the interconnecting rods are mounted inside the door, which makes them more challenging to install and tune.

Additional options for aluminum storefront doors

There is a special group of products designed for aluminum storefront doors. These include spring latch, security bolt locks and exit devices. The narrow frames that make up the structure of aluminum doors allow for attractive entrances but require locking hardware with unique and smaller dimensions than wood or steel doors.

Spring latches for aluminum doors can be operated by push or pull paddles, lever handles, thumb-turns or key cylinders.

The staff at K.M. Thomas can help you choose the correct door hardware for your next project and will be happy to answer questions about available lock functions and finishes. We have the knowledge to direct you to the best product for any application and we have the variety of stock to support your immediate door hardware needs.

Please send me an email or give us a call for more information.

Rene Widauer

K.M. Thomas Company Ltd.

Email: rene.w@kmthomas.com

Toll Free: 1-888-383-4105